Rolls-Royce, Airbus and Siemens say electric propulsion plans are clear for take-off, though the reality may take a little longer

EMAIL, the e-cig, e-commerce, e-filing… and the e-plane. Well, the E-Fan X hybrid aircraft, actually, rather prosaically described by one of its developers as “the world’s most powerful flying generator”.

Airbus, Rolls-Royce, and Siemens have formed a partnership which aims at developing a flight demonstrator which will be a significant step forward in hybrid-electric propulsion for commercial aircraft.

The three companies recently announced the collaboration at the Royal Aeronautical Society in London.

The E-Fan X hybrid-electric technology demonstrator is expected to take to the air in 2020, following a ground test campaign, provisionally on a BAe 146 flying testbed with one of the aircraft’s four gas turbine engines replaced by a 2MW (two megawatt) electric motor. Provisions will be made to replace a second gas turbine with an electric motor once system maturity has been proven.

“The E-Fan X is an important next step in our goal of making electric flight a reality in the foreseeable future. The lessons we learned from a long history of electric flight demonstrators … will pave the way to a hybrid single-aisle commercial aircraft that is safe, efficient, and cost-effective,” said Paul Eremenko, Airbus CTO. “We see hybrid-electric propulsion as a compelling technology for the future of aviation.”

The E-Fan X demonstrator will explore the challenges of high-power propulsion systems: thermal effects, electric thrust management, altitude and dynamic effects on electric systems and electromagnetic compatibility issues. The objective is to mature the technology, performance, safety and reliability, enabling swift progress on the hybrid electric technology.

The programme also aims to establish the requirements for future certification of electrically powered aircraft while training a new generation of designers and engineers to bring hybrid-electric commercial aircraft closer to reality.

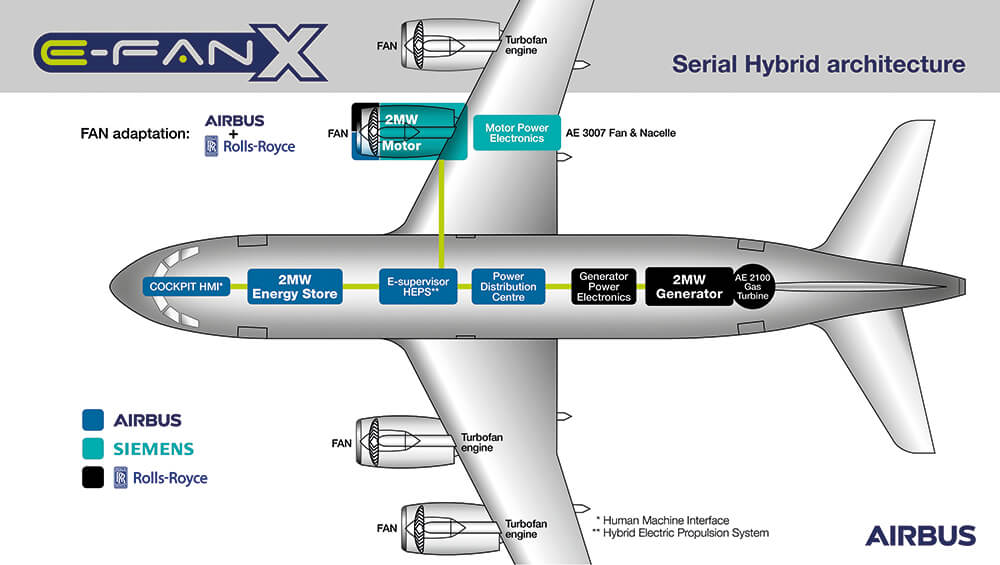

As part of the E-Fan X programme, Airbus, Rolls-Royce, and Siemens will each contribute in their respective fields of expertise.

Airbus will be responsible for overall integration and the control architecture of the hybrid-electric propulsion system and batteries, and its integration with flight controls.

Rolls-Royce will be responsible for the turbo-shaft engine, 2MW generator, and power electronics. Along with Airbus, Rolls-Royce will also work on the fan adaptation to the existing nacelle and the Siemens electric motor.

Siemens will deliver the two megawatt electric motors and their power electronic control unit, as well as the inverter, DC/DC converter, and power distribution system.

This comes on top of the E-Aircraft Systems House collaboration between Airbus and Siemens, launched in 2016, which to develop various electric propulsion system components and their terrestrial demonstration across various power classes.

Rolls-Royce CTO Paul Stein described the development as revolutionary.

“The E-Fan X enables us to build on our wealth of electrical expertise to revolutionise flight and welcome in the third generation of aviation. This is an exciting time for us as this technological advancement will result in Rolls-Royce creating the world’s most powerful flying generator.”

Siemens has been pursuing this angle for years. Roland Busch, the company’s CTO, said this represented “a new chapter, creating new perspectives”.

With the E-Fan X partnership, he said, “we now take the next step to demonstrate the technology in the air”.

Improved environmental performance, more efficient and less reliant on fossil fuels, is something of a holy grail. The partners are committed to meeting the EU technical environmental goals of the European Commission’s Flightpath 2050 Vision for Aviation (reduction of CO2 by 75 percent, reduction of NOx by 90 percent and noise reduction by 65 percent).

These cannot be achieved with existing technology, and electric and hybrid-electric propulsion are seen as the most promising technologies to meet the challenge.